How this Czech high-purity manganese project could help the EU meet its EV battery goals

Time:Wed, 31 Mar 2021 06:55:13 +0800

keywords :

- The growing electric vehicle (EV) trend is accelerating demand for essential battery raw materials like high-purity manganese (HPM)

- As the European Union (EU) looks to strengthen its EV supply chain, it is actively seeking local sources of HPM and other battery components

- Euro Manganese’s environmentally friendly Chvaletice Manganese Project in the Czech Republic positions the company to meet a large portion of the EU’s HPM requirements

The European Union (EU) is making a concerted push to electrify its auto industry as rapidly as possible. That drive has led to a parallel effort to localize its EV and lithium-ion battery supply chains.

One battery raw material of particular interest is high-purity manganese (HPM), an essential input in nickel-manganese-cobalt (NMC) batteries, which are increasingly in demand for EVs.

Derived from a highly refined form of manganese metal, the high-purity manganese sulphate (HPMSM) used to produce NMC batteries has exacting purity requirements that can be challenging and expensive for producers to meet.

As Andrew Zemek, a senior metal market researcher with CPM Group notes, “There’s no shortage of manganese and there’s no shortage of manganese sulphate. It’s the supply of high-purity manganese that’s constrained.”

He continues, “High-purity manganese is not a commodity like Grade A copper. Purity levels are king, and environmental footprint is important, especially in Europe, where buyers are willing to pay a premium for products that meet their ESG requirements."

Meanwhile, European governments and regulators are raising their standards. Battery raw materials must meet increasingly stringent sustainability criteria. For cost, ethical and corporate responsibility reasons, automakers are anxious to engineer every gram of cobalt they can out of NMC batteries. Given this trend, demand for comparatively inexpensive HPM is expected to grow, both due to increasing NMC battery production and a growing percentage of HPM used in those batteries.

Sam Jaffe, managing director of Cairn Energy Research Advisors, follows the battery market closely. He projects that the battery industry's demand for high-purity manganese will increase at a ten-year compound annual growth rate of 33.6 per cent. That's the highest rate of growth for any battery material.

It’s this confluence of trends that sets up Canadian company, Euro Manganese (TSXV/ASX: EMN), to capitalize, thanks to its centrally located, environmentally friendly Chvaletice Manganese Project.

“Chvaletice is the EU’s only realistic opportunity for local, large-scale primary production of battery-grade manganese.”

— Marco Romero, President & CEO, Euro Manganese Inc.

A recycling opportunity, not a mining project

Chvaletice’s location in the Czech Republic puts it at the heart of Europe’s EV and battery supply chain. Importantly, Chvaletice is a recycling opportunity, not a mining project.

It is an old tailings deposit from a decommissioned mine that has been impacting the local area’s water supply for decades. The deposit happens to contain Europe’s largest manganese resource. By processing these tailings, Euro Manganese will produce an estimated 49,000 tonnes per year of HPM and, at the same time, help to remediate the site.

That production level would make Chvaletice one of the world’s largest producers of HPM.

Euro Manganese’s President and CEO, Marco Romero, notes, “Chvaletice is the EU’s only realistic opportunity for local, large-scale primary production of battery-grade manganese.”

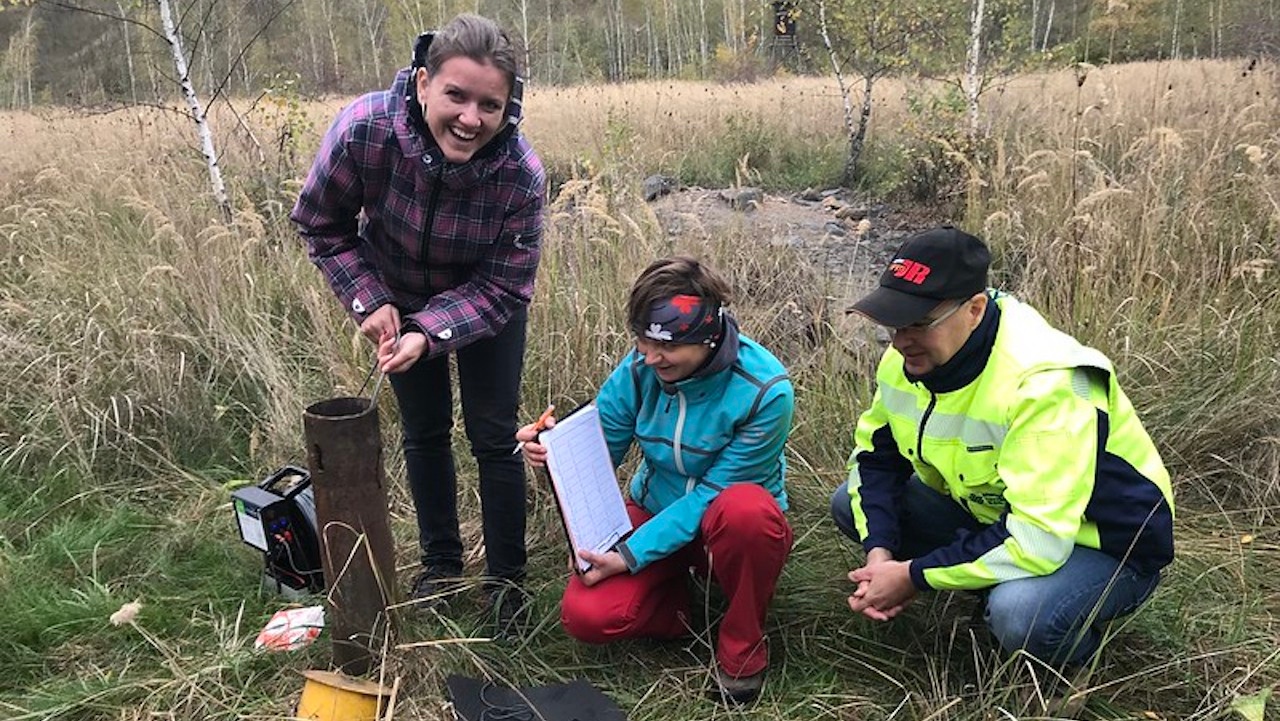

The company built and operated a pilot plant in 2018, which confirmed that reprocessing the tailings can produce battery-grade manganese products that meet the specifications of the most demanding HPM customers, using proven, commercial technology.

Also, the fact that Chvaletice can produce HPM in such a sustainable way has attracted the attention and support of EIT InnoEnergy, a European Union-backed body focused on accelerating the development of the EU’s sustainable energy and battery supply chains.

A critical agreement

In February, Euro Manganese inked a deal with EIT InnoEnergy that secures support to accelerate the funding and commercial development of the Chvaletice Project.

EIT InnoEnergy manages the European Battery Alliance, a group created by the EU that includes almost the entire EV/battery ecosystem. Its mandate is to support industry stakeholders in developing a robust EV and battery supply chain within the EU. Members include auto and battery makers, along with cathode, precursor, component, technology and raw materials companies.